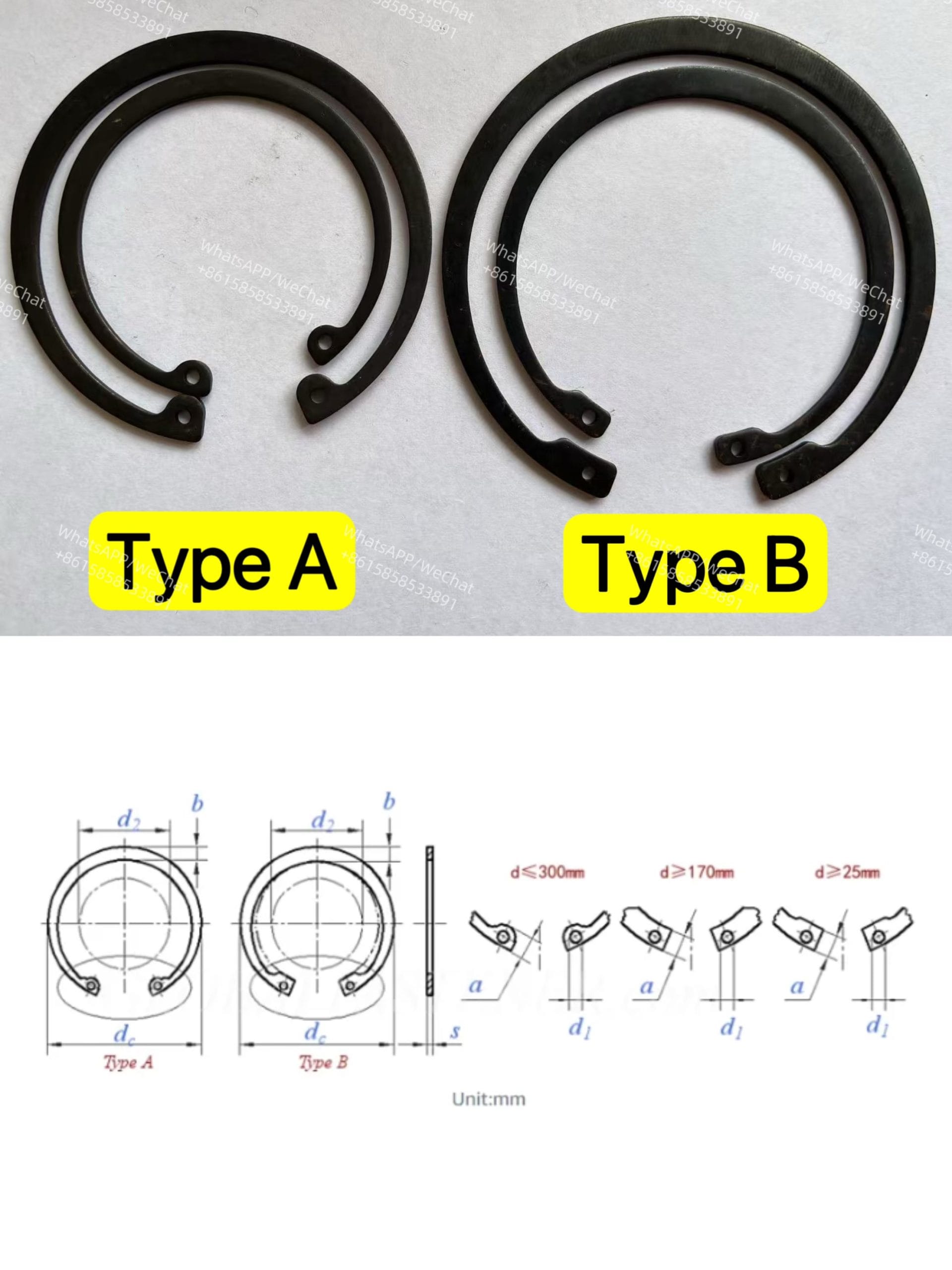

Wolun Pneumatic DIN 471 Circlips Retaining Rings for Shafts are designed to securely hold components in place on shafts, providing a reliable solution for retaining applications.DIN 471 standard ensures precise dimensions and a secure fit, while the Normal Type (Figure B) design allows for easy installation and removal, making maintenance simple and efficient. These retaining rings are commonly used in automotive, machinery, and electrical industries to prevent components from sliding off shafts or axles. Available in a wide range of sizes, they meet GB894 and DIN 471 specifications, providing a dependable, cost-effective fastening solution for various industrial needs.

Wolun Pneumatic E-style rings, these rings have three prongs that make contact with the shaft and provide a wider shoulder than other external rings for a larger retaining surface. Use a side-mount retaining ring tool (sold separately) to push them into the groove from the side of the shaft. Ring OD is measured with the ring uninstalled.

1060–1090 spring steel and spring steel rings are an economical choice with good strength. A black-phosphate finish is mildly corrosion resistant in dry environments. In wet environments, a zinc yellow-chromate plated finish has some corrosion resistance, and a zinc-chromate plated finish has good corrosion resistance.

DIN 1.4122 stainless steel rings withstand wear caused by abrasion, similar to 400 series stainless steel. Rings are passivated for added protection against corrosion.

15–7 PH stainless steel rings have high strength with good corrosion resistance. Rings are passivated for added protection against corrosion.

Thrust load capacity, also known as PR, is based on using a shaft that is harder than the ring.

Application Scenarios

- •Heavy Industry: Construction machinery, mining equipment, and hydraulic systems.

- •Automotive: Transmission systems, bearing retention, and engine components.

- •Infrastructure: Industrial pumps, valves, and conveyor systems.

- •Energy: Wind turbines, power generation equipment, and nuclear facilities.

- •Furniture & Hardware: High-end furniture joints and sliding mechanisms

Common Materials and Their Applications in Industrial Components

| Material | Description & Applications |

|---|

| 65Mn Steel | High carbon steel with excellent hardness and wear resistance. Commonly used for springs, tools, and automotive parts requiring high strength and durability. |

| 316 Stainless Steel | Austenitic stainless steel known for its exceptional corrosion resistance, especially in marine and chemical environments. Ideal for food processing, pharmaceuticals, and marine applications. |

| 304 Stainless Steel | The most widely used stainless steel with good corrosion resistance, formability, and weldability. Commonly used in kitchen equipment, architectural applications, and chemical industries. |

| Carbon Steel (Q235) | Low-carbon steel with good weldability and strength. Widely used in construction, automotive, and manufacturing industries for structural components. |

| Alloy Steel (4140) | Medium-carbon steel alloyed with chromium and molybdenum, offering high strength and toughness. Common in manufacturing of shafts, gears, and heavy-duty machinery parts. |

| Brass | Copper-zinc alloy known for its machinability and corrosion resistance. Used in plumbing, electrical components, and decorative items. |

| ألومنيوم | Lightweight metal with good corrosion resistance, used in aerospace, automotive, and construction industries for components requiring strength-to-weight ratio. |

| Titanium | Known for high strength, low weight, and excellent corrosion resistance, especially in aerospace, medical implants, and high-performance applications. |

Surface Treatment Process Selection Guide for Steel Washers

| Surface Treatment | Description & Applications |

|---|

| Dacromet | A chrome-free zinc coating offering excellent corrosion resistance. Suitable for automotive and industrial equipment exposed to harsh environments. |

| Galvanizing (Zinc Plating) | Zinc coating applied through electroplating or hot-dip, providing strong corrosion protection. Common in construction, outdoor machinery, and pipelines. |

| Black Oxide (Blackening) | A chemical oxidation process that creates a black, protective layer on steel. Ideal for mechanical parts, automotive components, and tools where appearance and corrosion resistance are important. |

| Zinc-Chromate Coating | A zinc coating with added chromium for enhanced corrosion resistance. Used in aerospace, and high-performance applications. |

| Nickel Plating | A nickel coating providing high hardness and excellent corrosion resistance, with a smooth surface. Used in electronics, precision parts, and industrial applications requiring high gloss and protection. |

| Phosphating | A process that forms a phosphate layer on the metal surface, improving adhesion and corrosion resistance. Used in automotive and machinery applications requiring good paint adhesion. |

| Aluminum Spraying | A coating of aluminum sprayed onto steel surfaces for heat and corrosion resistance. Used in high-temperature environments like boilers and engines. |

| Passivation | A process that enhances the corrosion resistance of stainless steel or aluminum by creating a protective oxide layer. Common in food processing, pharmaceutical, and medical equipment. |

| Coating (Polymer, Resin) | A thin film of polymers (e.g., polyurethane, epoxy) applied to the surface for corrosion resistance and wear protection. Used in electronics, appliances, and architectural applications. |