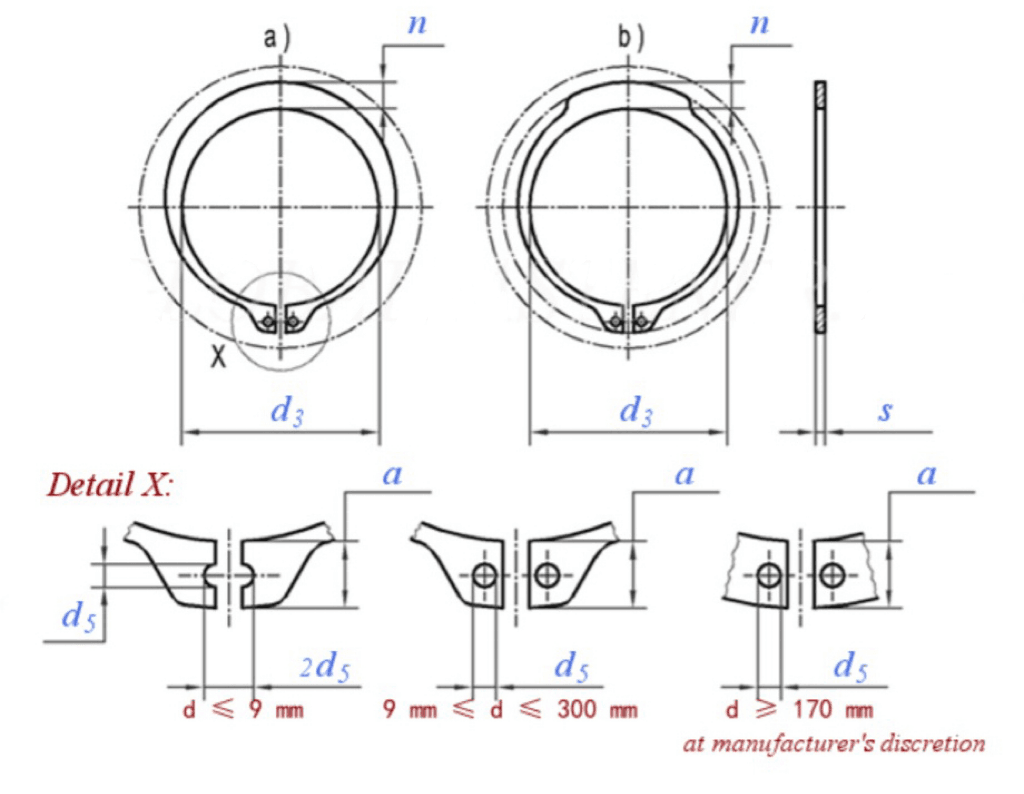

DIN 471 Retaining Rings For Shafts(external) Circlip

DIN 471 retaining rings for shafts are a connecting part commonly used in mechanical equipment. It is usually used to fix and support the shaft. As a company specializing in the production of various connecting parts, Wolun Pneumatic has rich production experience and technology accumulation for DIN 471 Retaining Rings For Shafts.

Product Description

There are two main types of retaining rings: internal and external. Internal retaining rings fit inside a bore or housing, while external retaining rings fit over a shaft or pin . Both types are available in various configurations, including tapered, spiral, and constant section.

DIN 471 retaining rings for shafts are a connecting part commonly used in mechanical equipment. It is usually used to fix and support the shaft.

| Unit:mm | |||||||||||||||||||||

| Nominal Diameter | 5 | 6 | 7 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | ||||||||||

| S | 0.4 | 0.4 | 0.6 | 0.7 | 0.8 | 0.8 | |||||||||||||||

| 0.35 | 0.35 | 0.55 | 065 | 0.75 | 0.75 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | |||||||

| d₃ | maX | 2.74 | 3.74 | 4.74 | 5.64 | 6.56 | 7.46 | 8.46 | 9.4 | 10.3 | 11.1 | 12 | 13 | 13.9 | 14.8 | 15.8 | |||||

| 2.55 | 3.55 | 4.55 | 5.45 | 6.32 | 7.22 | 8.22 | 8.94 | 9.84 | 10.64 | 11.54 | 12.54 | 13.44 | 14.34 | 15.34 | |||||||

| d₅ | 1.2 | 1.2 | 1.2 | 1.2 | 1.5 | 1.5 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | |||||||||

| maX | 1.9 | 2.2 | 2.5 | 2.7 | 3.1 | 3.2 | 3.3 | 3.3 | 3.3 | 3.3 | 3.4 | 3.5 | 3.6 | 3.7 | 3.8 | ||||||

| n | 0.8 | 0.9 | 1.1 | 1.3 | 1.4 | 1.5 | 1.7 | 1.8 | 1.8 | 1.8 | 2 | 2.1 | 2.2 | 2.2 | 2.3 | ||||||

| per 1000 units =kg | 0.017 | 0.022 | 0.066 | 0.084 | 0.121 | 0.158 | 0.300 | 0.340 | 0.410 | 0.500 | 0.530 | 0.640 | 0.670 | 0.700 | 0.820 | ||||||

| Nominal Diameter d |

18 | 19 | 20 | 21 | 22 | 24 | 25 | 26 | 28 | 29 | 30 | 32 | 34 | 35 | 36 | ||||||

| S | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.75 | ||||||

| min | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.44 | 1.44 | 1.44 | 1.44 | 1.44 | 1.44 | 1.69 | ||||||

| d₃ | maX | 16.6 | 17.6 | 18.63 | 19.63 | 20.63 | 22.41 | 23.41 | 24.41 | 26.11 | 27.11 | 28.11 | 29.81 | 31.75 | 32.45 | 33.45 | |||||

| 16.14 | 17.14 | 18.08 | 19.08 | 20.08 | 21.78 | 22.78 | 23.78 | 25.48 | 26.48 | 27.48 | 29.18 | 31 | 31.7 | 32.7 | |||||||

| d₅ | min | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2.5 | 2.5 | 2.5 | 2.5 | ||||||||

| a | max | 3.9 | 3.9 | 4.1 | 4.2 | 4.4 | 4.4 | 4.5 | 4.7 | 4.8 | 5.2 | 5.4 | 5.6 | 5.6 | |||||||

| n | 2.4 | 2.5 | 2.6 | 2.7 | 2.8 | 3 | 3.1 | 3.2 | 3.4 | 3.5 | 3.6 | 3.8 | 3.9 | 4 | |||||||

| per 1000units=kg | 1.11 | 1.22 | 1.30 | 1.42 | 1.50 | 1.77 | 1.90 | 1.96 | 2.92 | 3.2 | 3.3 | 3.54 | 3.8 | 4.00 | 5.00 | ||||||

| Nominal Diameter d |

38 | 40 | 42 | 45 | 48 | 50 | 52 | 55 | 56 | 58 | 60 | 62 | 63 | 65 | 68 | ||||||

| S | ma) | 1.75 | 1.75 | 1.75 | 1.75 | 1.75 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2.5 | 2.5 | ||||||

| 1.69 | 1.69 | 1.69 | 1.69 | 1.69 | 1.93 | 1.93 | 1.93 | 1.93 | 1.93 | 1.93 | 1.93 | 1.93 | 2.43 | 2.43 | |||||||

| d₃ | 35.45 | 36.89 | 38.89 | 41.89 | 44.89 | 46.19 | 48.19 | 51.26 | 52.26 | 54.26 | 56.26 | 58.26 | 59.26 | 61.26 | 63.96 | ||||||

| 34.7 | 35.6 | 37.6 | 40.6 | 43.6 | 44.9 | 46.9 | 49.7 | 50.7 | 52.7 | 54.7 | 56.7 | 57.7 | 59.7 | 62.4 | |||||||

| d₅ | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 3 | 3 | ||||||

| a | max | 5.8 | 6 | 6.5 | 6.7 | 6.9 | 6.9 | 7 | 7.2 | 7.3 | 7.3 | 7.4 | 7.5 | 7.6 | 7.8 | 8 | |||||

| n | 4.2 | 4.4 | 4.5 | 4.7 | 5 | 5.1 | 5.2 | 5.4 | 5.5 | 5.6 | 5.8 | 6 | 6.2 | 6.3 | 6.5 | ||||||

| per 1000 units =kg | 5.62 | 6.03 | 6.50 | 7.50 | 7.90 | 10.2 | 11.1 | 11.4 | 11.8 | 12.6 | 12.9 | 14.3 | 15.9 | 18.2 | 21.8 | ||||||

| Nominal Diamete | 70 | 72 | 75 | 78 | 80 | 82 | 85 | 88 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | ||||||

| S | max | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | |||||

| 2.43 | 2.43 | 2.43 | 2.43 | 2.43 | 2.43 | 2.92 | 2.92 | 2.92 | 2.92 | 2.92 | 3.9 | 3.9 | 3.9 | 3.9 | |||||||

| d3 | ma | 65.96 | 67.96 | 70.96 | 73.96 | 74.96 | 76.96 | 79.96 | 83.04 | 85.04 | 90.04 | 95.04 | 9854 | 103.54 | 108.54 | 113.54 | |||||

| 64.4 | 66.4 | 69.4 | 72.4 | 73.4 | 75.4 | 78.4 | 81.2 | 83.2 | 88.2 | 93.2 | 96.7 | 101.7 | 106.7 | 111.7 | |||||||

| d₅ | 3 | 3 | 3 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | |||||||||

| maX | 8.1 | 8.2 | 8.4 | 8.6 | 8.6 | 8.7 | 8.7 | 8.8 | 8.8 | 9.4 | 9.6 | 9.9 | 10.1 | 10.6 | 11 | ||||||

| n | 6.6 | 6.8 | 7.3 | 7.4 | 7.6 | 7.8 | 8 | 8.2 | 8.6 | 9 | 9.3 | 9.6 | 9.8 | 10.2 | |||||||

| per 1000units ≈kg | 22.0 | 22.5 | 24.6 | 26.2 | 27.3 | 31.2 | 36.4 | 41.2 | 44.5 | 49 | 53.7 | 80 | 82 | 84 | 86 | ||||||

| Nominal Diameter | 125 | 130 | 135 | 140 | 145 | 150 | 155 | 160 | 165 | 170 | 175 | 180 | 185 | 190 | 195 | ||||||

| S | ma) | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |||||

| min | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | ||||||

| d₃ | max | 118.54 | 123.63 | 128.63 | 133.63 | 138.63 | 142.63 | 146.63 | 151.63 | 156.13 | 161.13 | 166.13 | 171.03 | 176.13 | 181.22 | 186.22 | |||||

| 116.7 | 121.5 | 126.5 | 131.5 | 136.5 | 140.5 | 144.5 | 149.5 | 154 | 159 | 164 | 168.9 | 174 | 178.8 | 183.8 | |||||||

| d₅ | 4 | ||||||||||||||||||||

| maX | 11.4 | 11.6 | 11.8 | 12 | 12.2 | 13 | 13 | 13.3 | 13.5 | 13.5 | 13.5 | 14.2 | 14.2 | 14.2 | 14.2 | ||||||

| n | 10.4 | 10.7 | 11 | 11.2 | 11.5 | 11.8 | 12 | 12.2 | 125 | 12.9 | 12.9 | 13.5 | 13.5 | 14 | 14 | ||||||

| per 1000 units≈kg | 90 | 100 | 104 | 110 | 115 | 120 | 135 | 150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 | ||||||

| Nominal Diameter | 200 | 210 | 220 | 230 | 240 | 250 | 260 | 270 | 280 | 290 | 300 | ||||||||||

| s | maX | 4 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | ||||||||||||

| 3.9 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | |||||||||||

| d3 | 191.22 | 198.72 | 208.72 | 218.72 | 228.72 | 238.72 | 245.72 | 255.81 | 265.81 | 275.81 | 285.81 | ||||||||||

| 188.8 | 196.3 | 206.3 | 216.3 | 226.3 | 236.3 | 243.3 | 253 | 263 | 273 | 283 | |||||||||||

| d5 | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 | ||||||||||||

| max | 14.2 | 14.2 | 14.2 | 14.2 | 14.2 | 14.2 | 16.2 | 16.2 | 16.2 | 16.2 | 16.2 | ||||||||||

| 14 | 14 | 14 | 14 | 14 | 16 | 16 | 16 | 16 | 16 | ||||||||||||

| per 1000 units =kg | 230 | 248 | 265 | 290 | 310 | 335 | 355 | 375 | 398 | 418 | 440 | ||||||||||

aft diameter d≤48mm,470-580 HV or 47-54 HRC

mm mm

Related products

-

Pneumatic Cylinder Kit

Black GB858 Tab Stop Washers with Six Claws for Round Nuts

-

Pneumatic Cylinder Kit

Reverse Thread Hex Nuts Left Hand Thread Hex Nuts

-

Pneumatic Cylinder Kit

Pneumatic Air Cylinder Kits