DIN 471 Retaining Rings For Shafts(external) Circlip

DIN 471 Retaining Rings For Shafts has the characteristics of high strength and wear resistance, which can ensure a stable connection effect under high load and high-speed operation environment. Its surface has undergone precise heat treatment and surface treatment, and has good corrosion resistance and wear resistance, and can be used for a long time in harsh working environments.

Product Description

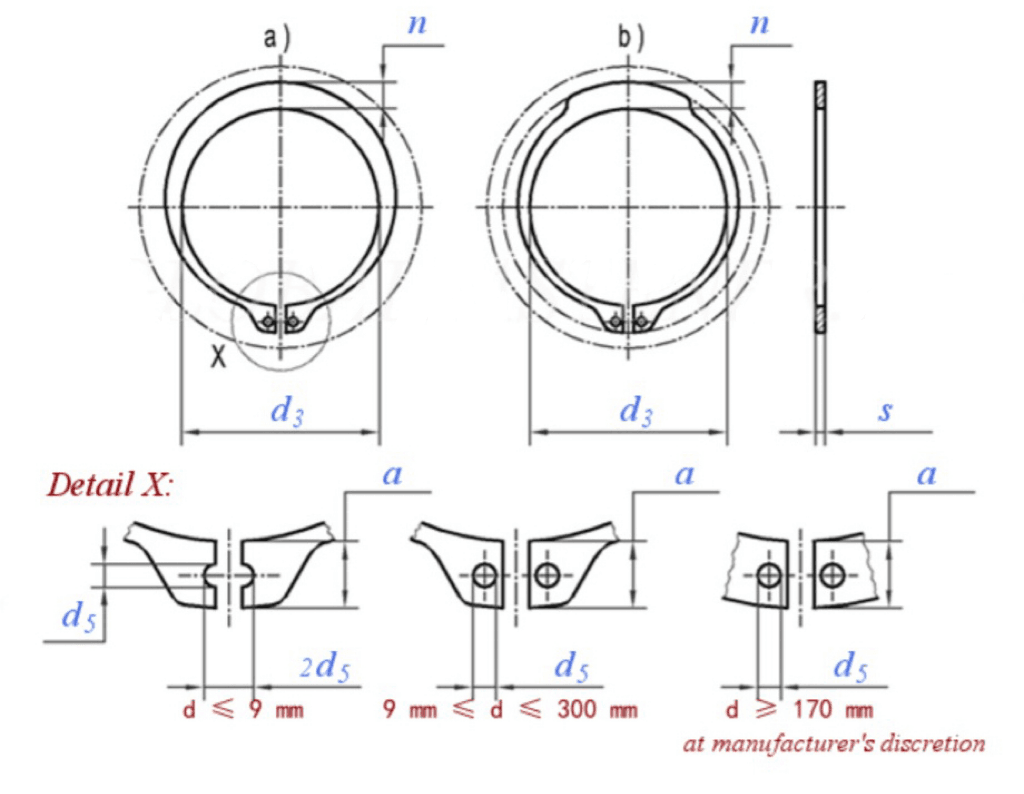

There are mainly two types of circlips: internal circlips and external circlips. The internal circlips are installed inside holes or bearing housings, while the external circlips are installed on shafts or pins. Both types of circlips have multiple configurations, including tapered, spiral and constant-section ones.

The shaft circlips conforming to DIN 471 are commonly used connecting parts in mechanical equipment and are usually employed for fixing and supporting shafts.

The fixing rings for shafts conforming to DIN 471 possess the characteristics of high strength and wear resistance, which can ensure a stable connection effect under high-load and high-speed operating environments. Their surfaces have undergone precise heat treatment and surface treatment, having good corrosion resistance and wear resistance, so they can be used for a long time in harsh working environments.

| Unit:mm | |||||||||||||||||||||

| Nominal Diameter | 5 | 6 | 7 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | ||||||||||

| S | 0.4 | 0.4 | 0.6 | 0.7 | 0.8 | 0.8 | |||||||||||||||

| 0.35 | 0.35 | 0.55 | 065 | 0.75 | 0.75 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | |||||||

| d₃ | maX | 2.74 | 3.74 | 4.74 | 5.64 | 6.56 | 7.46 | 8.46 | 9.4 | 10.3 | 11.1 | 12 | 13 | 13.9 | 14.8 | 15.8 | |||||

| 2.55 | 3.55 | 4.55 | 5.45 | 6.32 | 7.22 | 8.22 | 8.94 | 9.84 | 10.64 | 11.54 | 12.54 | 13.44 | 14.34 | 15.34 | |||||||

| d₅ | 1.2 | 1.2 | 1.2 | 1.2 | 1.5 | 1.5 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | |||||||||

| maX | 1.9 | 2.2 | 2.5 | 2.7 | 3.1 | 3.2 | 3.3 | 3.3 | 3.3 | 3.3 | 3.4 | 3.5 | 3.6 | 3.7 | 3.8 | ||||||

| n | 0.8 | 0.9 | 1.1 | 1.3 | 1.4 | 1.5 | 1.7 | 1.8 | 1.8 | 1.8 | 2 | 2.1 | 2.2 | 2.2 | 2.3 | ||||||

| per 1000 units =kg | 0.017 | 0.022 | 0.066 | 0.084 | 0.121 | 0.158 | 0.300 | 0.340 | 0.410 | 0.500 | 0.530 | 0.640 | 0.670 | 0.700 | 0.820 | ||||||

|

Nominal Diameter d |

18 | 19 | 20 | 21 | 22 | 24 | 25 | 26 | 28 | 29 | 30 | 32 | 34 | 35 | 36 | ||||||

| S | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.75 | ||||||

| min | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.14 | 1.44 | 1.44 | 1.44 | 1.44 | 1.44 | 1.44 | 1.69 | ||||||

| d₃ | maX | 16.6 | 17.6 | 18.63 | 19.63 | 20.63 | 22.41 | 23.41 | 24.41 | 26.11 | 27.11 | 28.11 | 29.81 | 31.75 | 32.45 | 33.45 | |||||

| 16.14 | 17.14 | 18.08 | 19.08 | 20.08 | 21.78 | 22.78 | 23.78 | 25.48 | 26.48 | 27.48 | 29.18 | 31 | 31.7 | 32.7 | |||||||

| d₅ | min | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2.5 | 2.5 | 2.5 | 2.5 | ||||||||

| a | max | 3.9 | 3.9 | 4.1 | 4.2 | 4.4 | 4.4 | 4.5 | 4.7 | 4.8 | 5.2 | 5.4 | 5.6 | 5.6 | |||||||

| n | 2.4 | 2.5 | 2.6 | 2.7 | 2.8 | 3 | 3.1 | 3.2 | 3.4 | 3.5 | 3.6 | 3.8 | 3.9 | 4 | |||||||

| per 1000units=kg | 1.11 | 1.22 | 1.30 | 1.42 | 1.50 | 1.77 | 1.90 | 1.96 | 2.92 | 3.2 | 3.3 | 3.54 | 3.8 | 4.00 | 5.00 | ||||||

|

Nominal Diameter d |

38 | 40 | 42 | 45 | 48 | 50 | 52 | 55 | 56 | 58 | 60 | 62 | 63 | 65 | 68 | ||||||

| S | ma) | 1.75 | 1.75 | 1.75 | 1.75 | 1.75 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2.5 | 2.5 | ||||||

| 1.69 | 1.69 | 1.69 | 1.69 | 1.69 | 1.93 | 1.93 | 1.93 | 1.93 | 1.93 | 1.93 | 1.93 | 1.93 | 2.43 | 2.43 | |||||||

| d₃ | 35.45 | 36.89 | 38.89 | 41.89 | 44.89 | 46.19 | 48.19 | 51.26 | 52.26 | 54.26 | 56.26 | 58.26 | 59.26 | 61.26 | 63.96 | ||||||

| 34.7 | 35.6 | 37.6 | 40.6 | 43.6 | 44.9 | 46.9 | 49.7 | 50.7 | 52.7 | 54.7 | 56.7 | 57.7 | 59.7 | 62.4 | |||||||

| d₅ | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 3 | 3 | ||||||

| a | max | 5.8 | 6 | 6.5 | 6.7 | 6.9 | 6.9 | 7 | 7.2 | 7.3 | 7.3 | 7.4 | 7.5 | 7.6 | 7.8 | 8 | |||||

| n | 4.2 | 4.4 | 4.5 | 4.7 | 5 | 5.1 | 5.2 | 5.4 | 5.5 | 5.6 | 5.8 | 6 | 6.2 | 6.3 | 6.5 | ||||||

| per 1000 units =kg | 5.62 | 6.03 | 6.50 | 7.50 | 7.90 | 10.2 | 11.1 | 11.4 | 11.8 | 12.6 | 12.9 | 14.3 | 15.9 | 18.2 | 21.8 | ||||||

| Nominal Diamete | 70 | 72 | 75 | 78 | 80 | 82 | 85 | 88 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | ||||||

|

S |

max | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | |||||

| 2.43 | 2.43 | 2.43 | 2.43 | 2.43 | 2.43 | 2.92 | 2.92 | 2.92 | 2.92 | 2.92 | 3.9 | 3.9 | 3.9 | 3.9 | |||||||

| d3 | ma | 65.96 | 67.96 | 70.96 | 73.96 | 74.96 | 76.96 | 79.96 | 83.04 | 85.04 | 90.04 | 95.04 | 9854 | 103.54 | 108.54 | 113.54 | |||||

| 64.4 | 66.4 | 69.4 | 72.4 | 73.4 | 75.4 | 78.4 | 81.2 | 83.2 | 88.2 | 93.2 | 96.7 | 101.7 | 106.7 | 111.7 | |||||||

| d₅ | 3 | 3 | 3 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | |||||||||

| maX | 8.1 | 8.2 | 8.4 | 8.6 | 8.6 | 8.7 | 8.7 | 8.8 | 8.8 | 9.4 | 9.6 | 9.9 | 10.1 | 10.6 | 11 | ||||||

| n | 6.6 | 6.8 | 7.3 | 7.4 | 7.6 | 7.8 | 8 | 8.2 | 8.6 | 9 | 9.3 | 9.6 | 9.8 | 10.2 | |||||||

| per 1000units ≈kg | 22.0 | 22.5 | 24.6 | 26.2 | 27.3 | 31.2 | 36.4 | 41.2 | 44.5 | 49 | 53.7 | 80 | 82 | 84 | 86 | ||||||

| Nominal Diameter | 125 | 130 | 135 | 140 | 145 | 150 | 155 | 160 | 165 | 170 | 175 | 180 | 185 | 190 | 195 | ||||||

|

S |

ma) | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |||||

| min | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | ||||||

| d₃ | max | 118.54 | 123.63 | 128.63 | 133.63 | 138.63 | 142.63 | 146.63 | 151.63 | 156.13 | 161.13 | 166.13 | 171.03 | 176.13 | 181.22 | 186.22 | |||||

| 116.7 | 121.5 | 126.5 | 131.5 | 136.5 | 140.5 | 144.5 | 149.5 | 154 | 159 | 164 | 168.9 | 174 | 178.8 | 183.8 | |||||||

| d₅ | 4 | ||||||||||||||||||||

| maX | 11.4 | 11.6 | 11.8 | 12 | 12.2 | 13 | 13 | 13.3 | 13.5 | 13.5 | 13.5 | 14.2 | 14.2 | 14.2 | 14.2 | ||||||

| n | 10.4 | 10.7 | 11 | 11.2 | 11.5 | 11.8 | 12 | 12.2 | 125 | 12.9 | 12.9 | 13.5 | 13.5 | 14 | 14 | ||||||

| per 1000 units≈kg | 90 | 100 | 104 | 110 | 115 | 120 | 135 | 150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 | ||||||

| Nominal Diameter | 200 | 210 | 220 | 230 | 240 | 250 | 260 | 270 | 280 | 290 | 300 | ||||||||||

| s | maX | 4 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | ||||||||||||

| 3.9 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | 4.88 | |||||||||||

| d3 | 191.22 | 198.72 | 208.72 | 218.72 | 228.72 | 238.72 | 245.72 | 255.81 | 265.81 | 275.81 | 285.81 | ||||||||||

| 188.8 | 196.3 | 206.3 | 216.3 | 226.3 | 236.3 | 243.3 | 253 | 263 | 273 | 283 | |||||||||||

| d5 | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 | ||||||||||||

| max | 14.2 | 14.2 | 14.2 | 14.2 | 14.2 | 14.2 | 16.2 | 16.2 | 16.2 | 16.2 | 16.2 | ||||||||||

| 14 | 14 | 14 | 14 | 14 | 16 | 16 | 16 | 16 | 16 | ||||||||||||

| per 1000 units =kg | 230 | 248 | 265 | 290 | 310 | 335 | 355 | 375 | 398 | 418 | 440 | ||||||||||

①,Hardness of tetaining rings:

aft diameter d≤48mm,470-580 HV or 47-54 HRC

mm mm

aft diameter d≤48mm,470-580 HV or 47-54 HRC

mm mm

Our Order Photos

Our company also can provide other Internal/External Circlip Snap Ring Set as below

280Pcs External Circlip Snap Ring Set

280Pcs Internal Circlip Snap Ring Set

200Pcs External Circlip Snap Ring Set

100Pcs External Circlip Snap Ring Set

137PCS Internal Circlip Snap Ring Set

Sản phẩm tương tự

-

Pneumatic Cylinder Kit

200Pcs External Circlip Snap Ring Set

-

Pneumatic Cylinder Kit

SC standard cylinder kits

-

Pneumatic Cylinder Kit

304 Stainless Steel Pneumatic cylinder Piston Rod, Stainless Steel Shaft

-

Pneumatic Cylinder Kit

Tie Rod